|

Overhead catenary on the Bernina Bahn

On this page I've first put the overhead catenary of Alp Grüm with a description

because this is the most interesting part due to the hairpin turn.

Next you will find the description of the station of Campocologno.

|

|

Our layout has to be equipped with Overhead wire, just like the original.

In model this is a job in itself because of the separations between the modules

that are needed for transport. The overhead wire must be tiled here and be able

to be taken apart without compromising the quality. This forms a challenge while

keeping the wire under tension. The turn underneath the station of Alp Grüm has

a special way of overhead construction. In the hairpin turn, the wire has not

been constructed in the usual way, it has been suspended only by the hanging wire.

The driving wire does not touch the post anywhere.

Click on the photos and drawings to get an

enlargement in a new window.

|

|

|

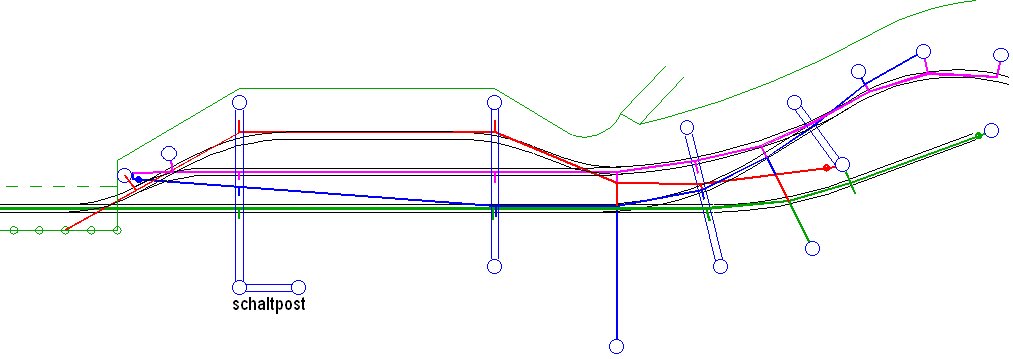

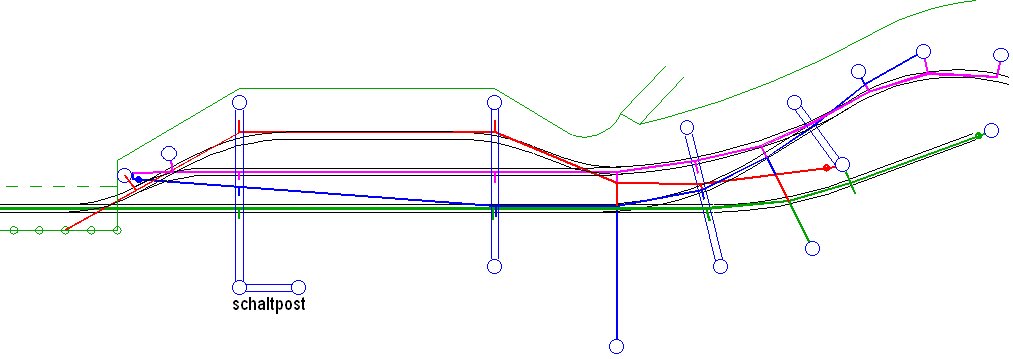

Wire scheme of Alp Grüm station

In the scheme above you can see how the individual wires traverse the

station of

Alp Grüm. One post catches the eye, it is positioned very far away

from the rails. This is done to prevent pedestrians from running

into it because it is right at the pedestrian crossing of the path

to the upper restaurant.

Here too you can click on the drawing to get a better picture. The

green wire comes from the direction of the pass. It ends in the

station where it is put under tension. The pink wire begins in the

station and continues down the hairpin curve. It is terminated

shortly after the turn. The red and blue wires remain entirely

within the station area.

In our model we will use this same scheme.

|

|

|

Changeover to the sharp turn

This photo of the original shows the transition from normally

suspended overhead wire to the stretched wire used during the turn.

On the first post, both the upper and the lower wire are directly

attached. On the middle post, the upper wire is directly attached

but the lower wire is pulled to the side by a special attachment,

consisting of a thinner part from the post and a thicker, curved,

part connecting to the lower wire. The rear post only holds the

upper wire and the lower wire hangs free during the whole turn,

connected to the pole via supporting wires. All supporting wires

that hold the lower wire are made of two parts, a thin part from

the upper wire and a think, curved, part to the lower wire.

This is done to prevent the pantograph from touching the supporting wires.

|

|

|

Marking the positions of our poles

Dec 2003

In the model station of Alp Grüm we started to mark the locations of the

poles that should carry our overhead wires. We did this through

orange pins.

On a number of places the poles will be connected to form a portal but this

is not used everywhere. because of the narrow turns we need to put

some extra poles in between to hold the wire in the middle of the

rail.

|

|

|

The first portal is standing

Alp Grüm in a later stage

(Christmas 2004), A part of the overhead catenary has taken its

place. In particular the turn after Alp Grüm. It showed that we have

to, just as in reality, tie up the poles in the curve to keep them

straight.

|

|

|

The wire has been installed

Situation 2006, Station Alp Grüm completely wired. Also the special

overhead wire in the turn is well visible. The material we used for

the horizontal wires is bronze, 0,7 mm thick. The wires have the

complete length of the station so that we don't need any weldings.

The little vertical wires are made of messing wire, 0,5 mm thick.

That is a lot easier to solder and cut. In order to bridge the gap

between two modules, we used short, ready made pieces by Sommerfeldt.

They can be removed easily for transport.

|

|

A short manual

For fastening the vertical wires we took the following approach;

You start by cutting off several wires to the desired length plus

about 1 cm. Those pieces can be attached to the lower wire by a

clothes peg. Do it so that the clothes peg only holds the vertical

wire and can still slide it over the lower horizontal wire. In this way

you can move all needed wires to a nice, equal distance. Now it is

easy to solder them one by one to the upper wire. the clothes pegs

can be removed and you can solder the other side to the lower wire.

Cut off excessive metal and make them smooth on the bottom. We did

that with an abrasive round stone on a mini drill. Ready to drive.

|

|

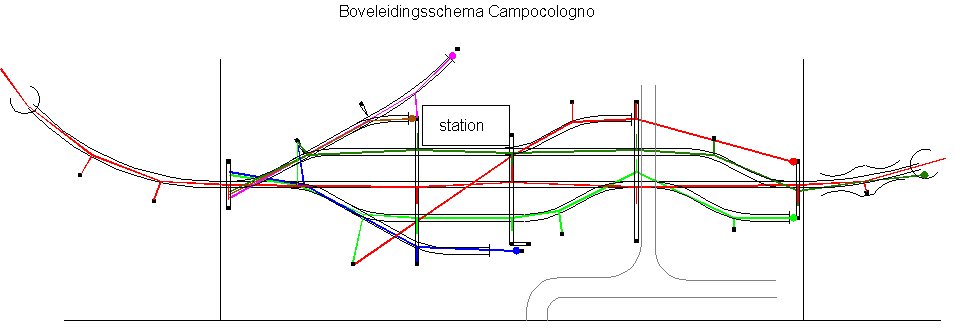

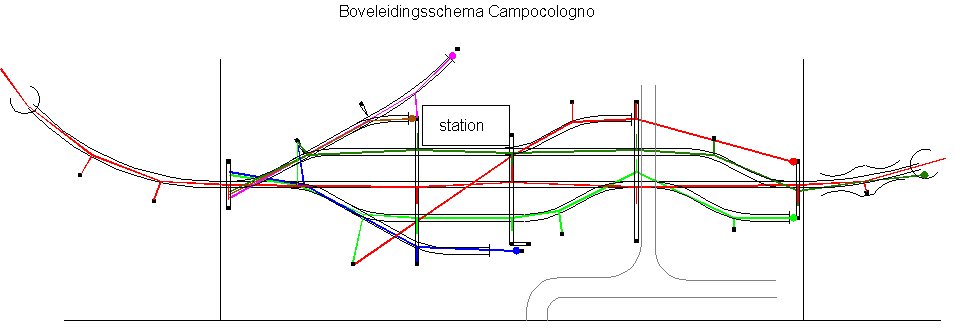

Wire scheme of Campocologno station

|

|

Campocologno under construction by Johan and Steef.

|

|

June 2006. The lower wires are ready, the upper wire and the

connecting wires are still to come.

|

|

April 2007. The overhead catenary is almost done.

A few pieces on the shunting tracks still have to be done but due to

lack of the right wire it can take a while.

Sunday 1 April 2007 we used the overhead catenary for the first time.

Click here for a small film in QuickTime format.

|

|

March 2008. De overhead wire can be shown at Rail.

All station tracks are under wire now.

The overhead wire is also powered, which is used for the internal

lighting of the train. The headlights and the lights in all

carriages burn constantly as long as the pantograph touches the

overhead wire. Also when the train comes to a halt as show on this

picture.

|

|

Tunnels ?

We did not make overhead wire everywhere in the tunnel. We omitted that

on all places where we had enough space to have the pantograph upright,

that would only have complicated things. An exception is the spiral.

Here the height till the track above is not enough and so we did attach

a thick wire to the ceiling using metal strips. We used electric

installation wire (1,5mm). Also directly behind all tunnel entrances we

used this wire to "catch" the pantograph. Mounting the wire

under the spiral was best done by putting the complete module upside down.

Then you can easily solder everything into place. To determine the position

of the wire we used a specially prepared wagon with a pencil mounted on top

of it. A spring held it to the ceiling while driving over the rails.

This gave a nice line on the ceiling which could be used for positioning when soldering.

Hans Hosang

|