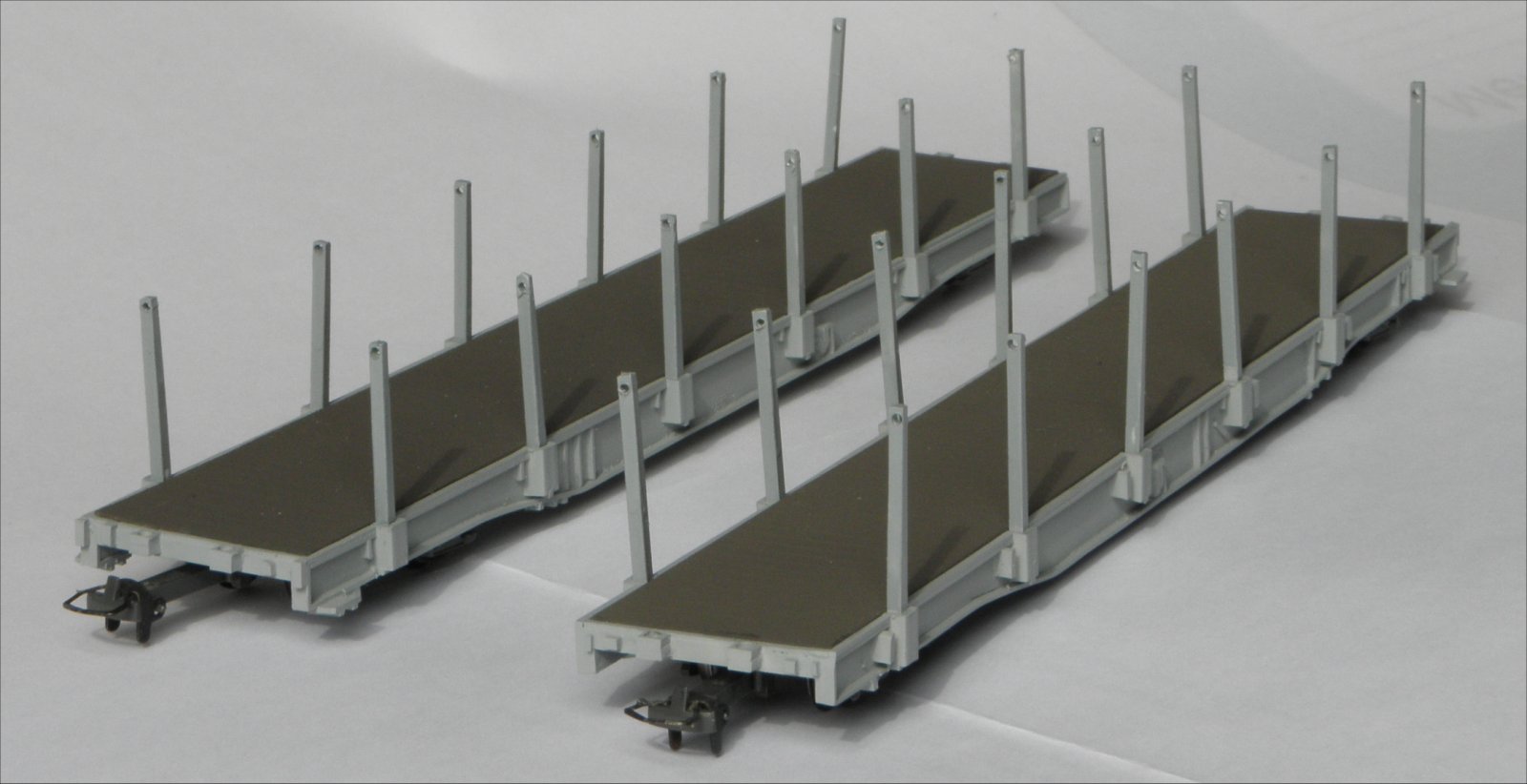

The old wagons

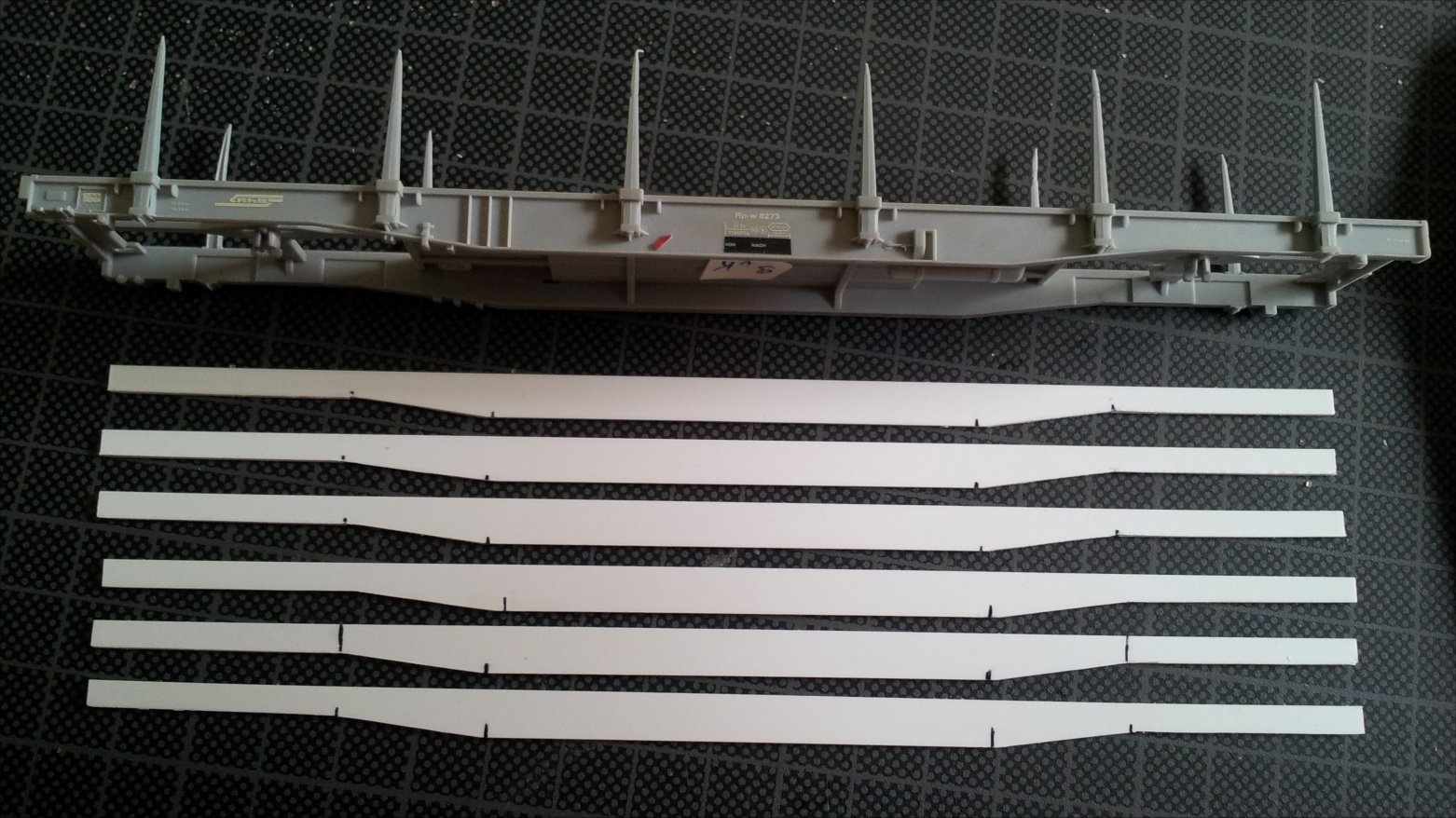

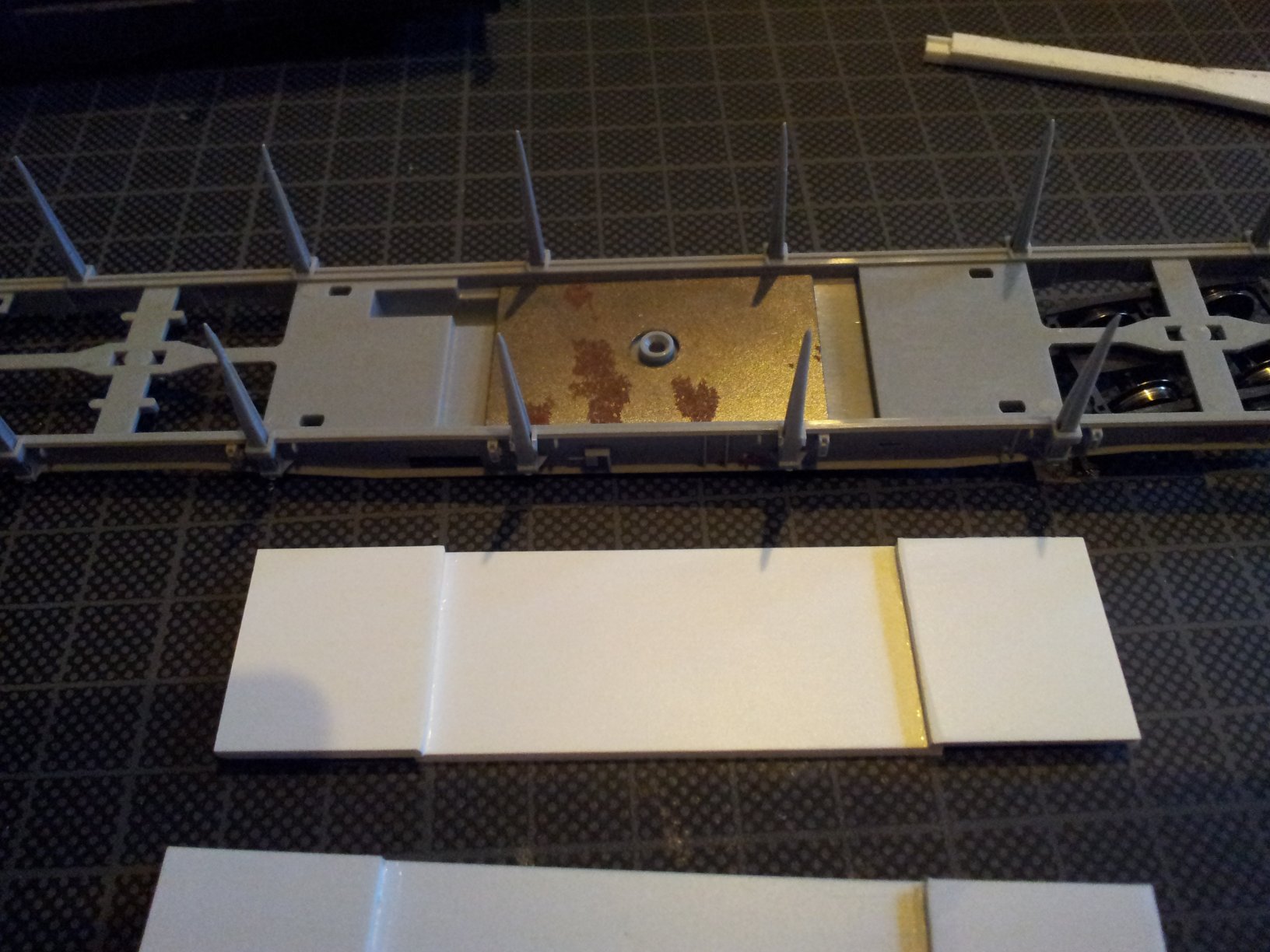

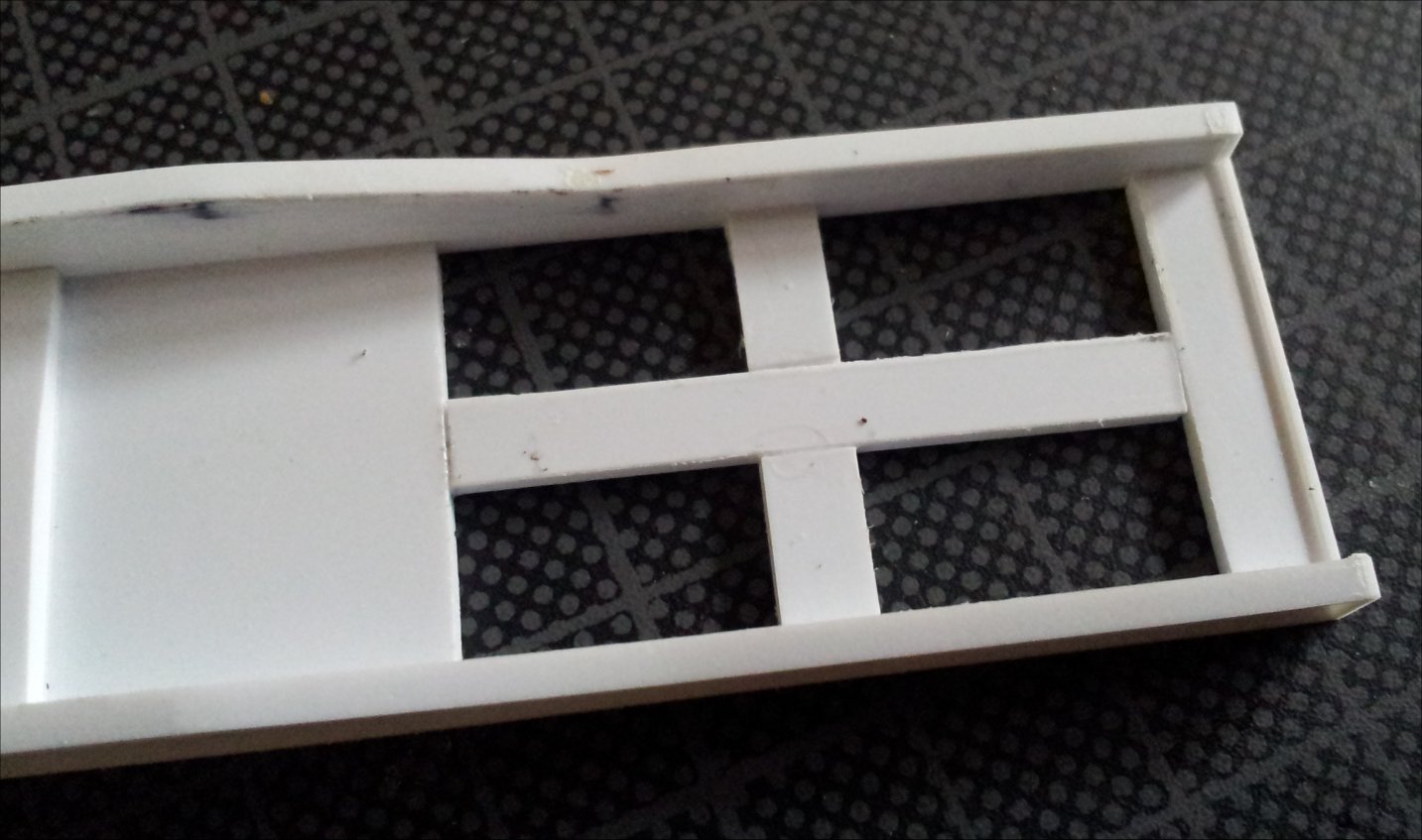

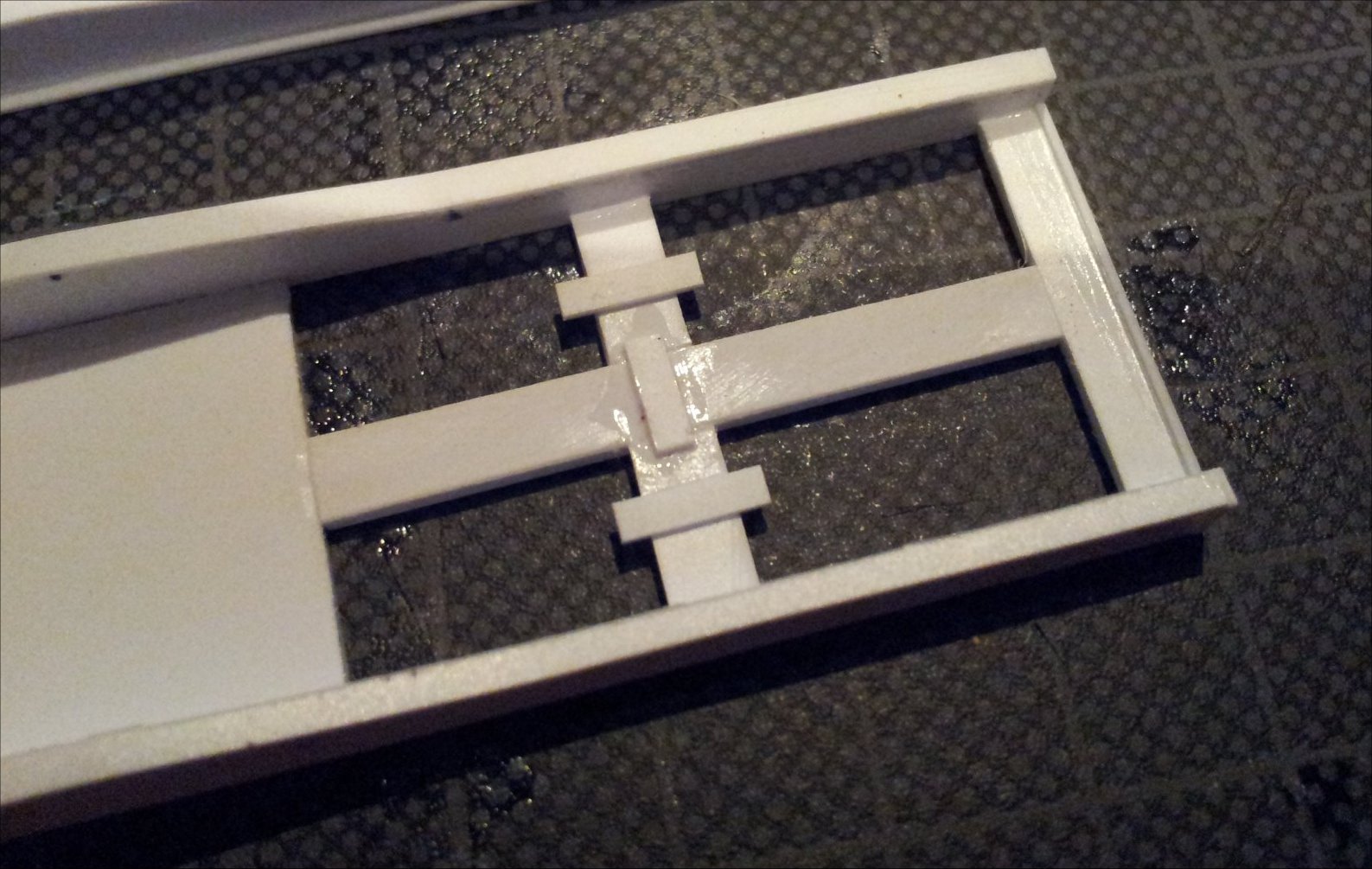

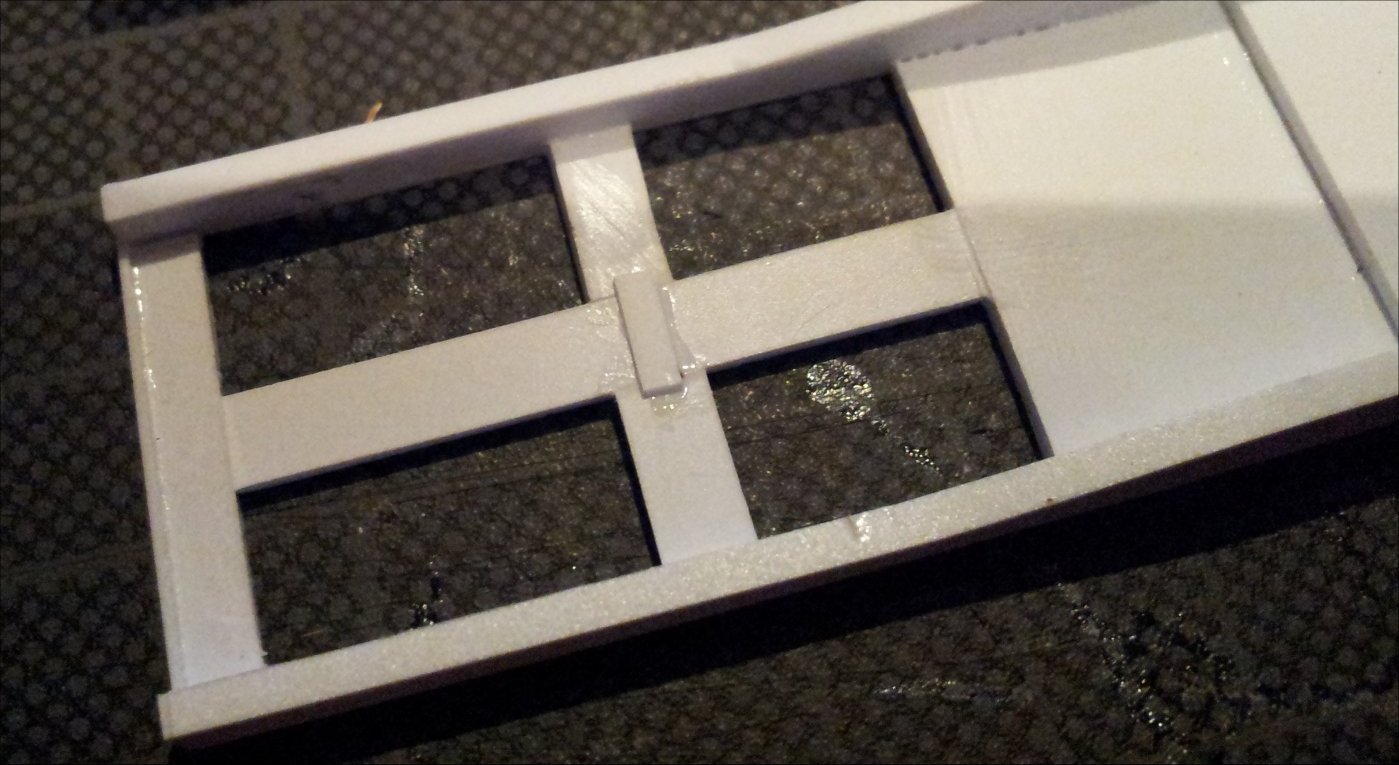

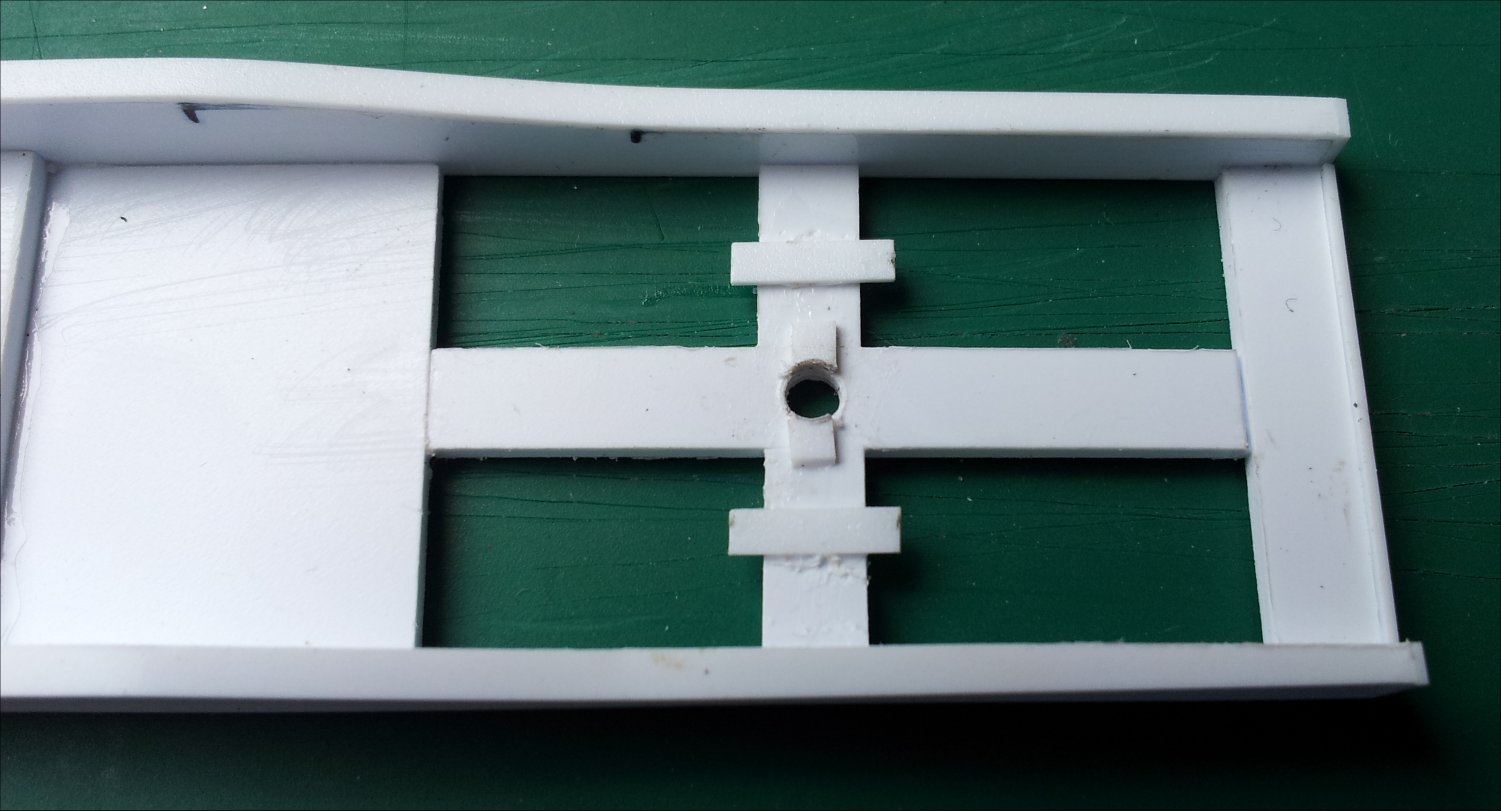

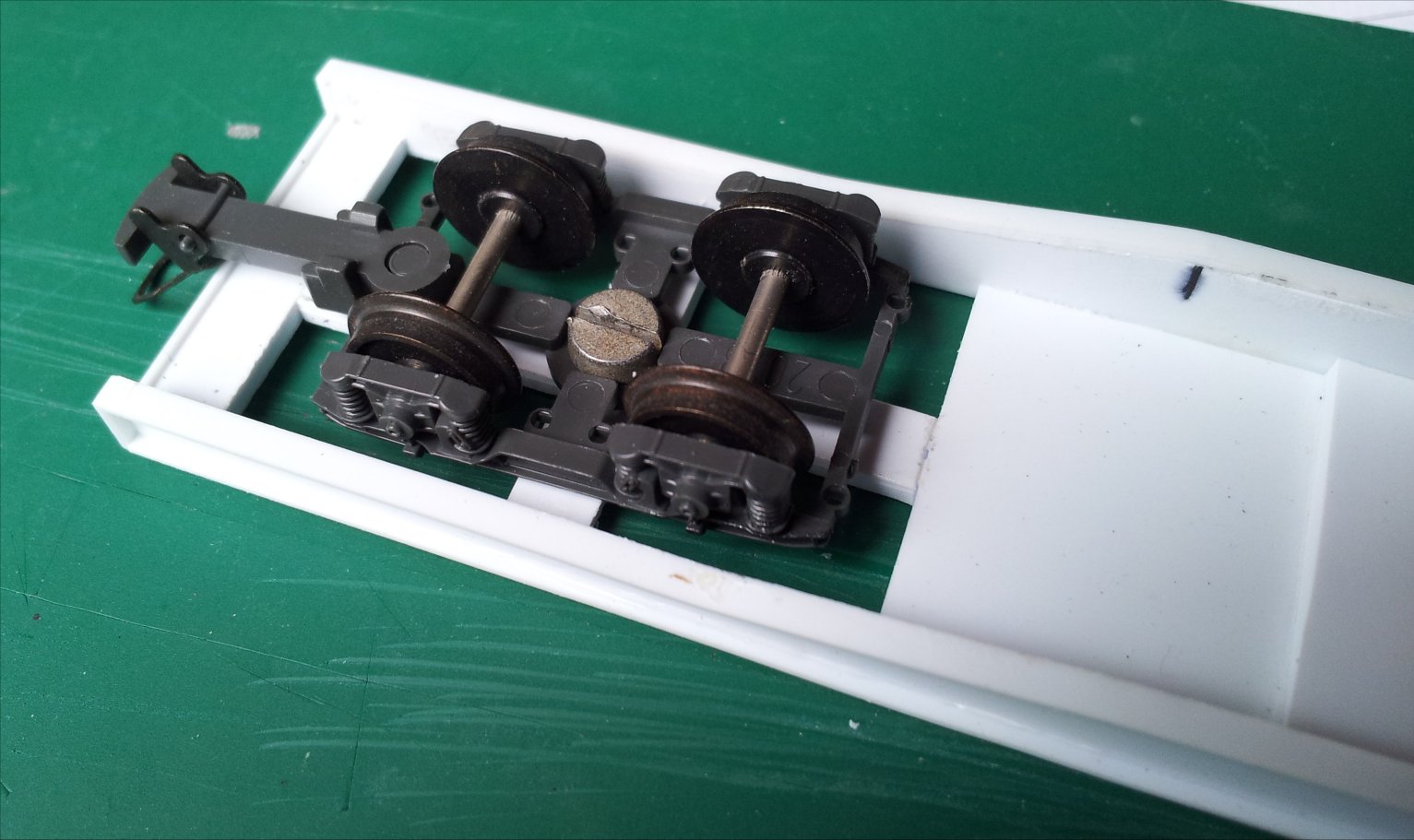

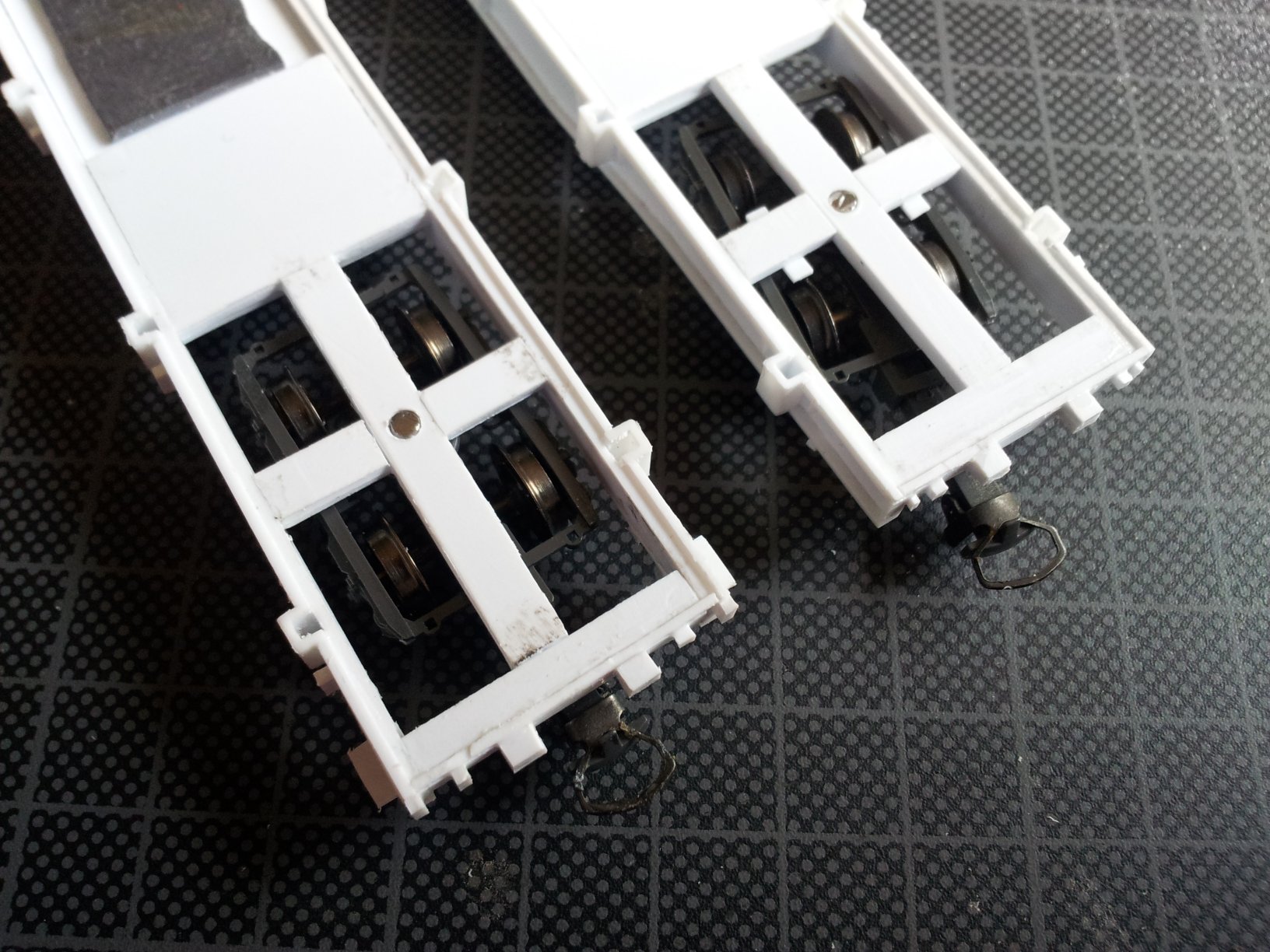

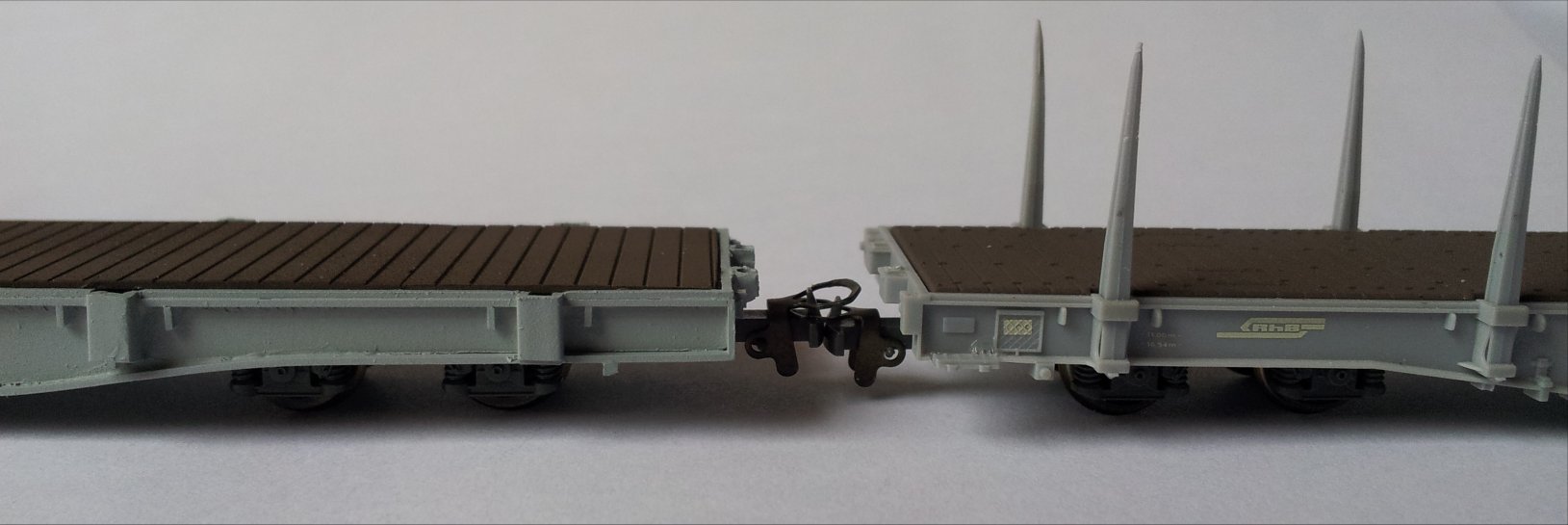

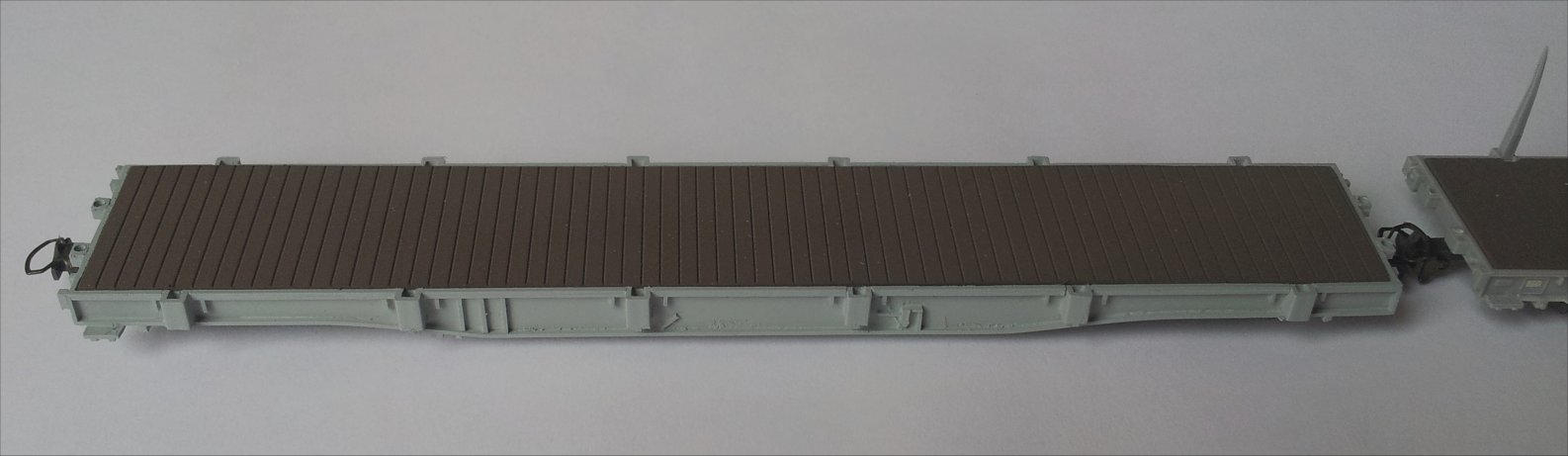

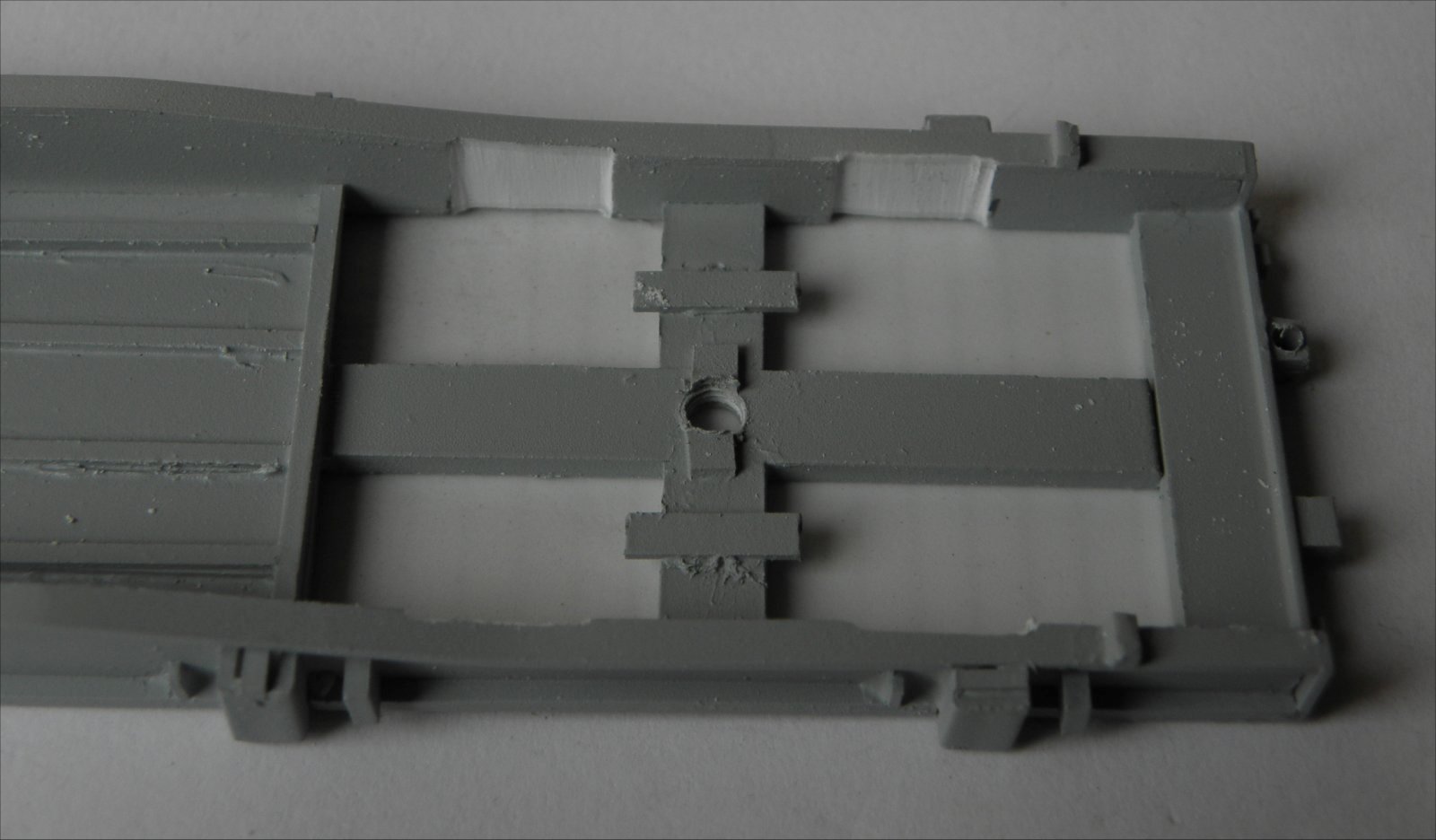

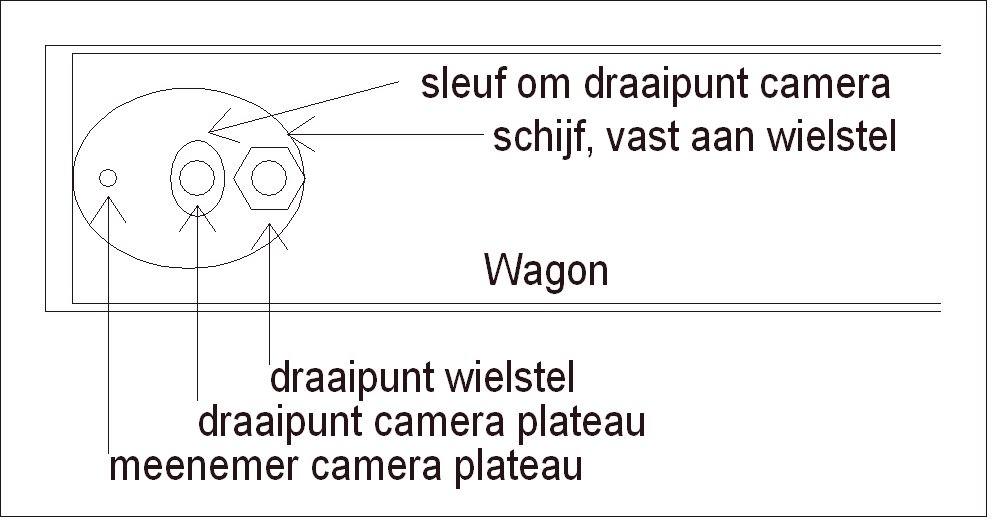

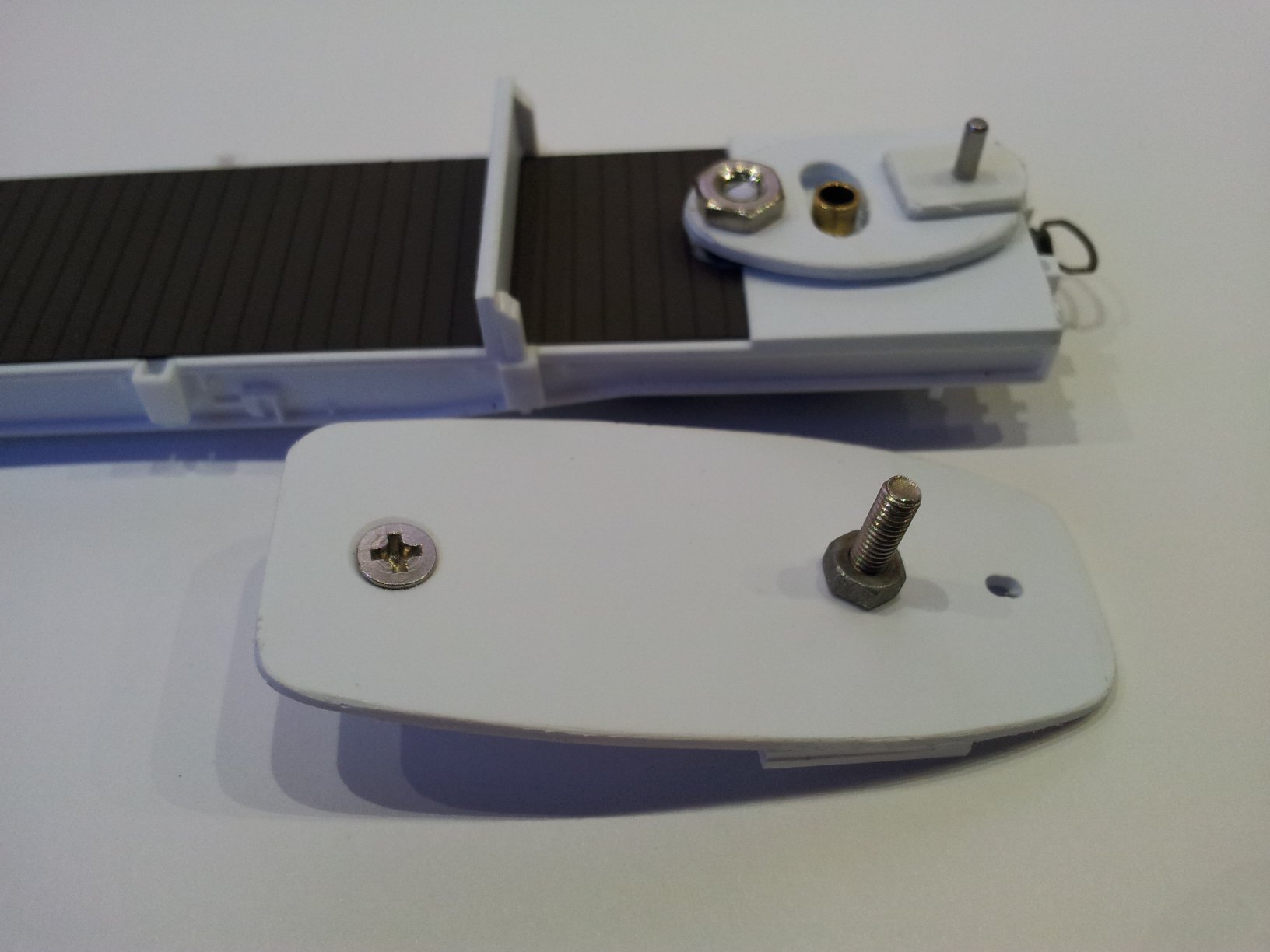

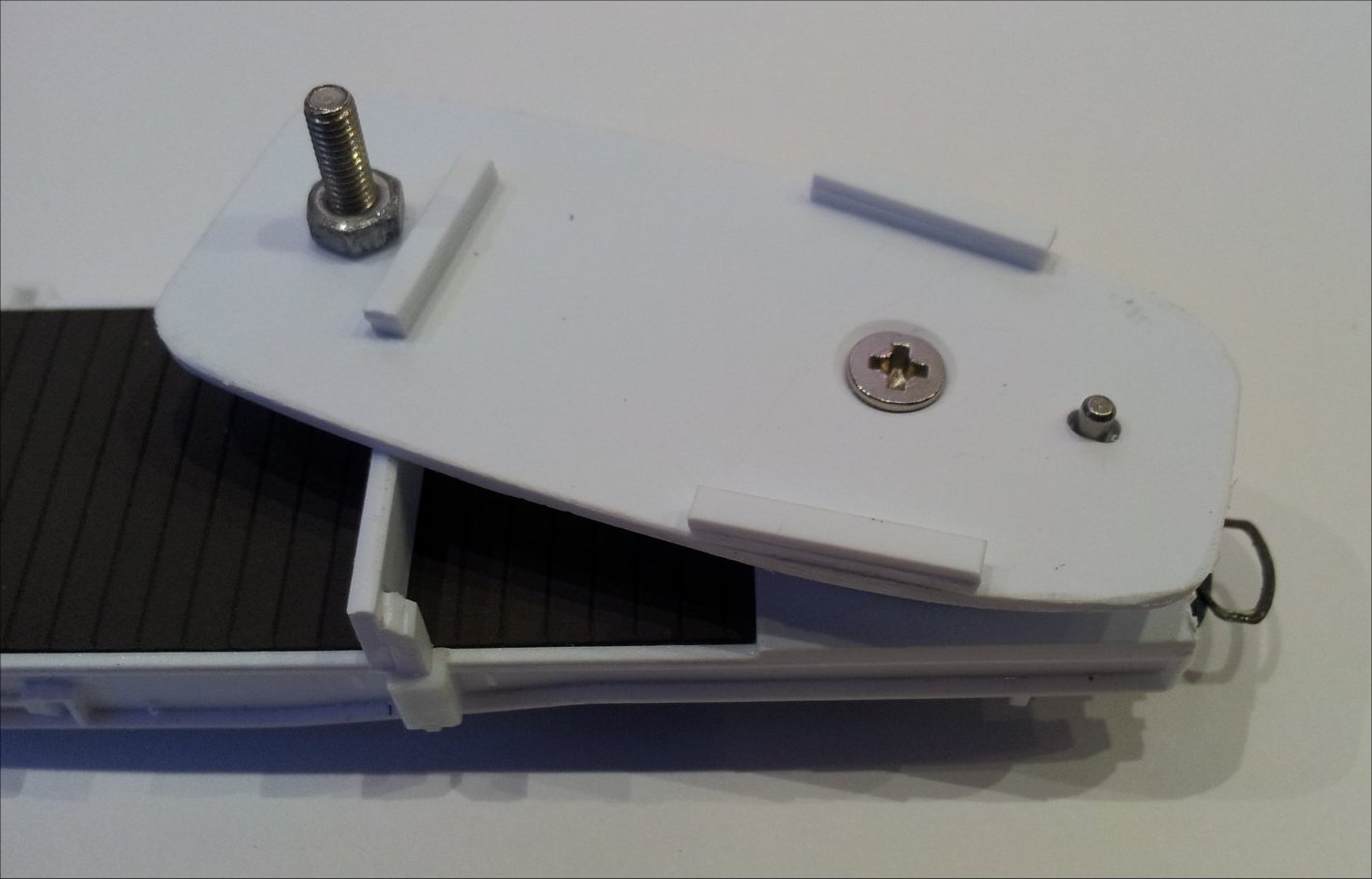

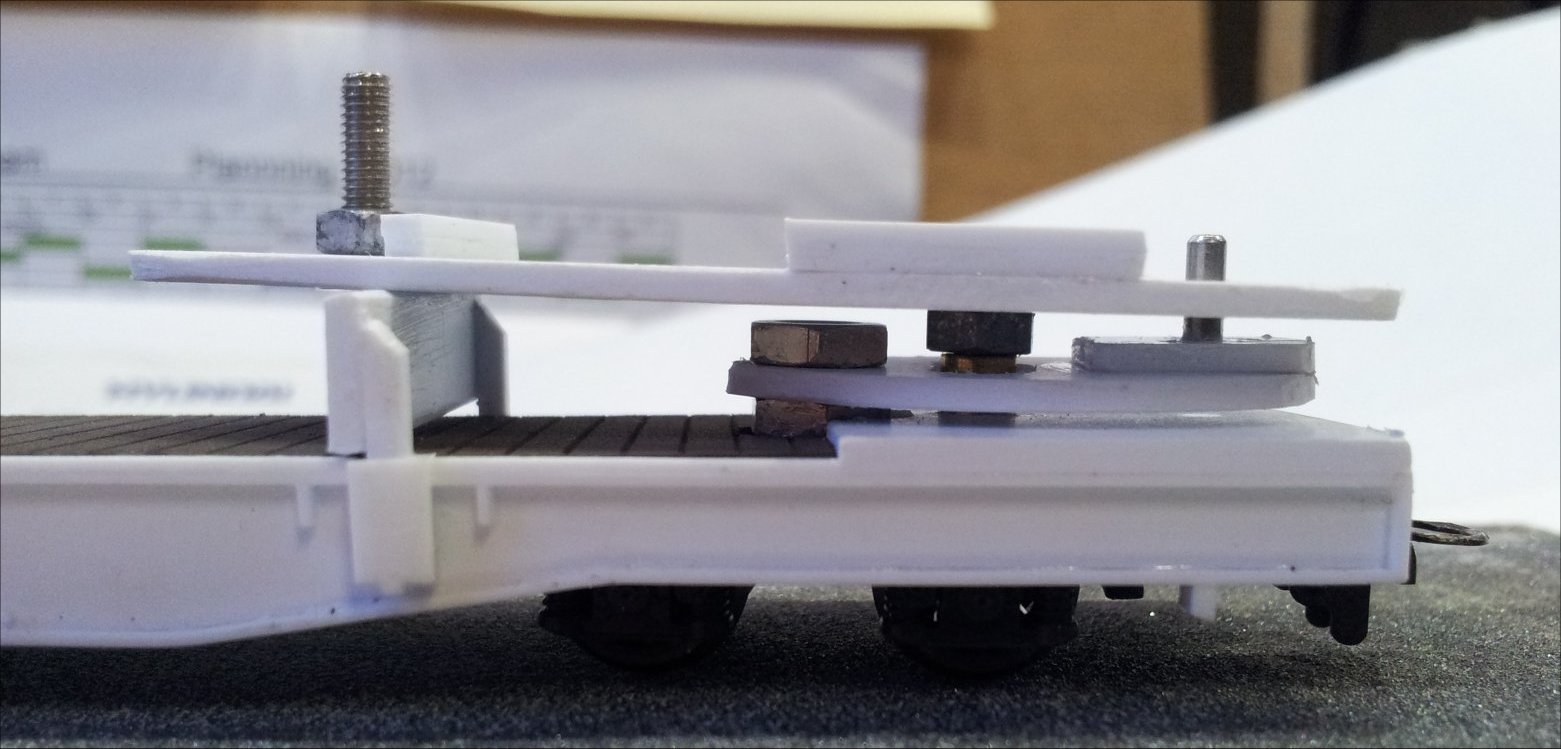

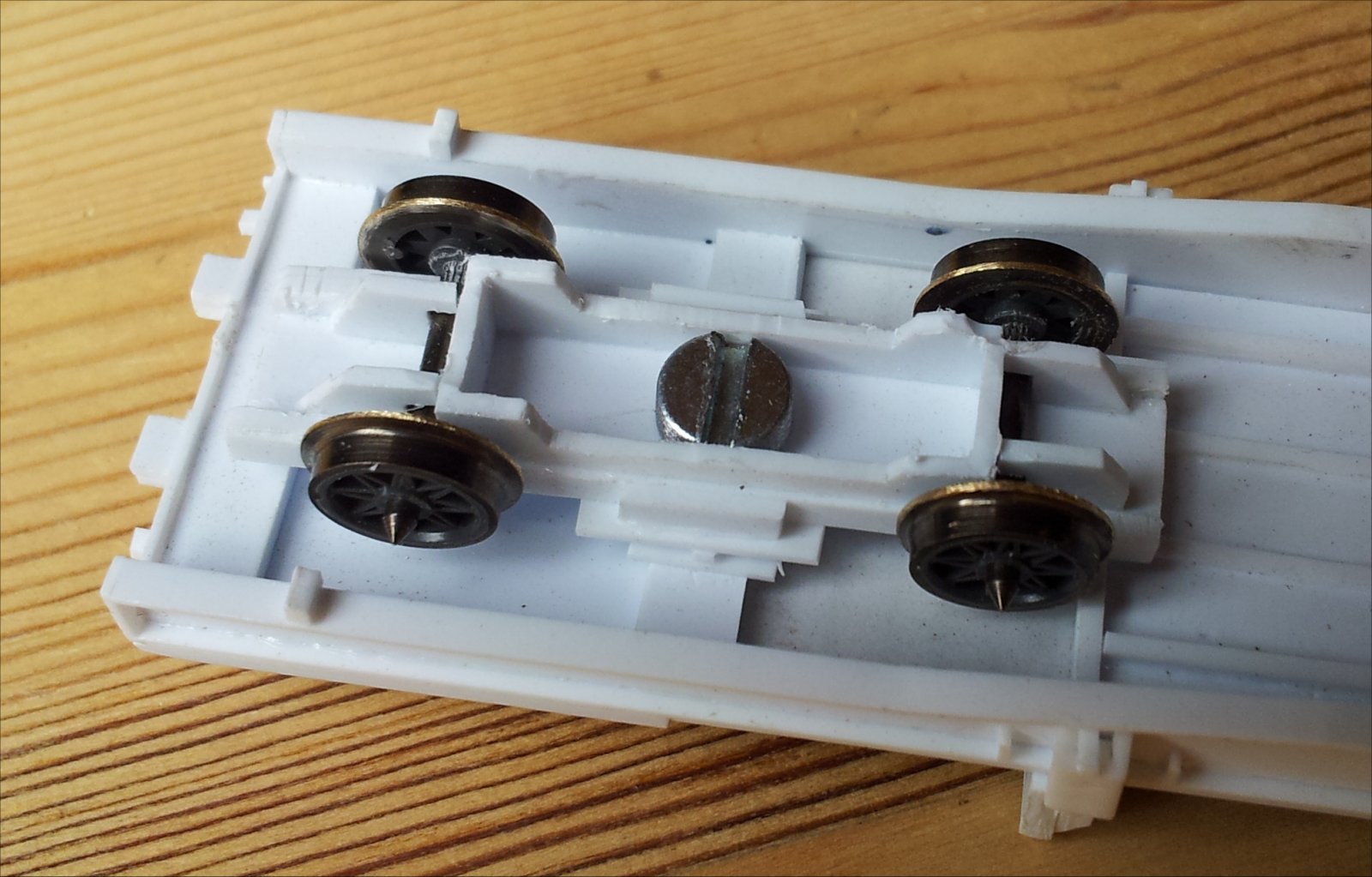

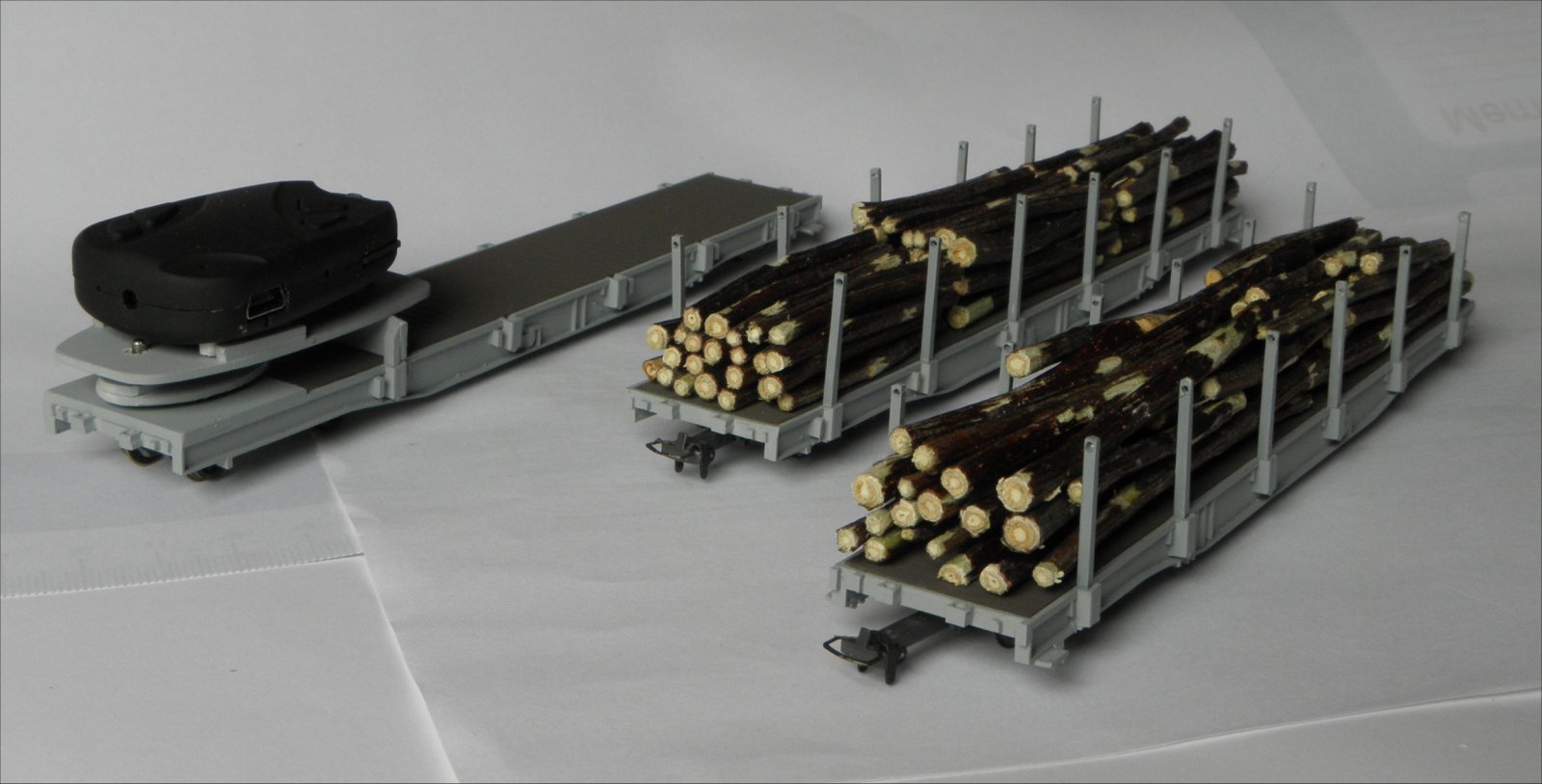

This was a petty as we were in need of some wagons for wood transport. To make this donation go though I decided to keep the bogies and use those to create 3 new wagons. During the planning the idea arose to make one of those cars fit to hold a camera. From multiple attempts to have a camera in front of a locomotive it turned out that the camera only shows what is outside a turn and does not show where you are going, it would be nice to have the camera turn farther then the bogies so that you can keep an eye on the rails. A wagon with bogies gives the option to transfer the movement of the bogies to the camera. With that principle I want to do some experimenting but now I'll guide you through the construction of the cars themselves.